Custom Tool Grinding & Sharpening

Tool Grinding Technology

3-Walter Power 500 5 Axis Tool and Cutter Grinders with Loaders

1 Anca TG7 5 Axis Grinder

1 Anca RGX 5 Axis Grinder

1 Tru-Tech Revolution CNC Centerless Grinder

1 TruTech T23X CNC OD Grinder

2 Okamoto 12X24 Surface Grinders

6 Cincinnati Monoset Tool and Cutter Grinders

3 Cincinnati #2 Universal Grinders

1 Hybco Cam Relief Grinder

2 Sheffield Microform Grinders

1 Colonial Broach Grinder

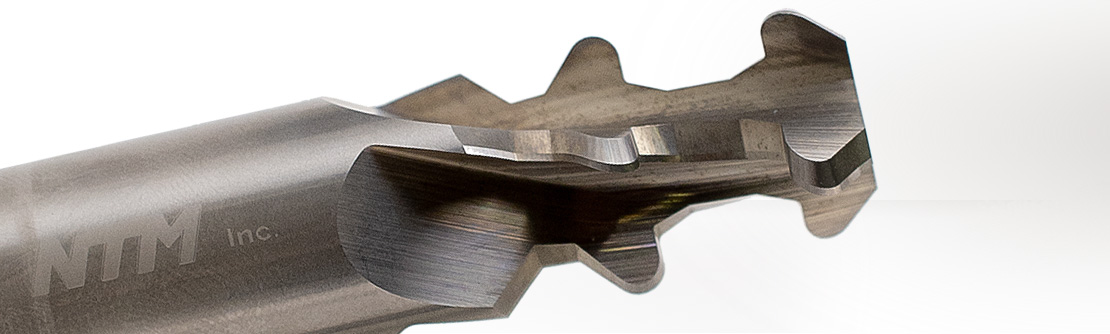

Tool Grinding and Sharpening Capabilities

Ability to process solid carbide, carbide tipped, and high- speed steel materials.

Precision Processes Include: Contour, fine grinding, form grinding, high speed grinding, precision grinding and polishing.

Coatings: Tin, Altin, TiCN, ZRN, ALCRN, TiCRN, CrN, TaC (PVD diamond)

- Carbide and HSS end mill/rougher end mills

- Carbide, HSS, and powdered metal drills

- Roto Broaches

- Unibits

- Gundrills

- Threadmills

- Engraving Tools

- Dead Centers

- Reamers

- Center Drills

- Keyway/woodruff cutters

- Spot Drills

- Corner Rounds

- Counterbores/potfacers

- Spade drill inserts

- Slitting Saws

- Broaches

- Taps

- Shapers Milling Cutters

- Centerless rest blades

- All types of carbide and HSS specials

- Dies, Dovetails, Shave Tools

- Re-Grind V-Blocks

*Re-Sharpening Tooling Disclaimer: Upon occasion while re-sharpening used tooling, damage may occur beyond repair, NTM will credit up to 30% of the replacement cost of the damaged tool.