Our Services

From customized design to CNC machining, NTM is here to help with all of your tooling needs.

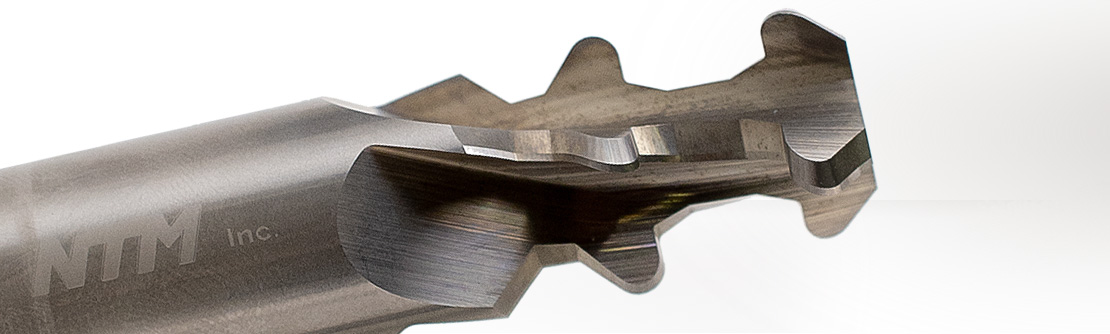

CUSTOM TOOL GRINDING & SHARPENING

Extend the life of your tooling investment with our regrinding and sharpening service. Many special coatings are available, just ask!

Let us know if you need an NTM reusable tote to transport your tools.

We have the ability to process solid carbide, carbide tipped, and high-speed steel materials.

Our precision processes include:

- Contouring

- Fine Grinding

- Form Grinding

- High-Speed Grinding

- Precision Grinding

- Polishing

Our tool grinding technology includes:

- 3-Walter Power 500 5 Axis Tool and Cutter Grinders with Loaders

- 1 Anca TG7 5 Axis Grinder

- 1 Anca RGX 5 Axis Grinder

- 1 Tru-Tech Revolution CNC Centerless Grinder

- 1 TruTech T23X CNC OD Grinder

- 6 Cincinnati Monoset Tool and Cutter Grinders

- 3 Cincinnati #2 Universal Grinders

- 1 Hybco Cam Relief Grinder

- 2 Sheffield Microform Grinders

- 3 Okamoto 12X24 Surface Grinders

Coatings: Tin, Altin, TiCN, ZRN, ALCRN, TiCRN, CrN, TaC (PVD diamond)

- Carbide and HSS end mill/rougher end mills

- Carbide, HSS, and powdered metal drills

- Unibits

- Gundrills

- Threadmills

- Engraving Tools

- Dead Centers

- Reamers

- Center Drills

- Keyway/Woodruff cutters

- Spot Drills

- Corner Rounds

- Counterbores/Spotfacers

- Spade drill inserts

- Slitting Saws

- Taps

- Shapers Milling Cutters

- Centerless rest blades

- All types of carbide and HSS specials

- Dies, Dovetails, Shave Tools

- Re-Grind V-Blocks

*Re-Sharpening Tooling Disclaimer: Upon occasion while re-sharpening used tooling, damage may occur beyond repair, in which case NTM will credit up to 30% of the replacement cost of the damaged tool.

Click here to learn more about our Custom Carbide Step Drill.

NU HEAD™

Need to repair damaged boring bars?

Nu Head™ is the best option for repairing damaged indexable boring bars. We manufacture over 150 different sizes of heads to quickly and accurately restore your damaged bars.

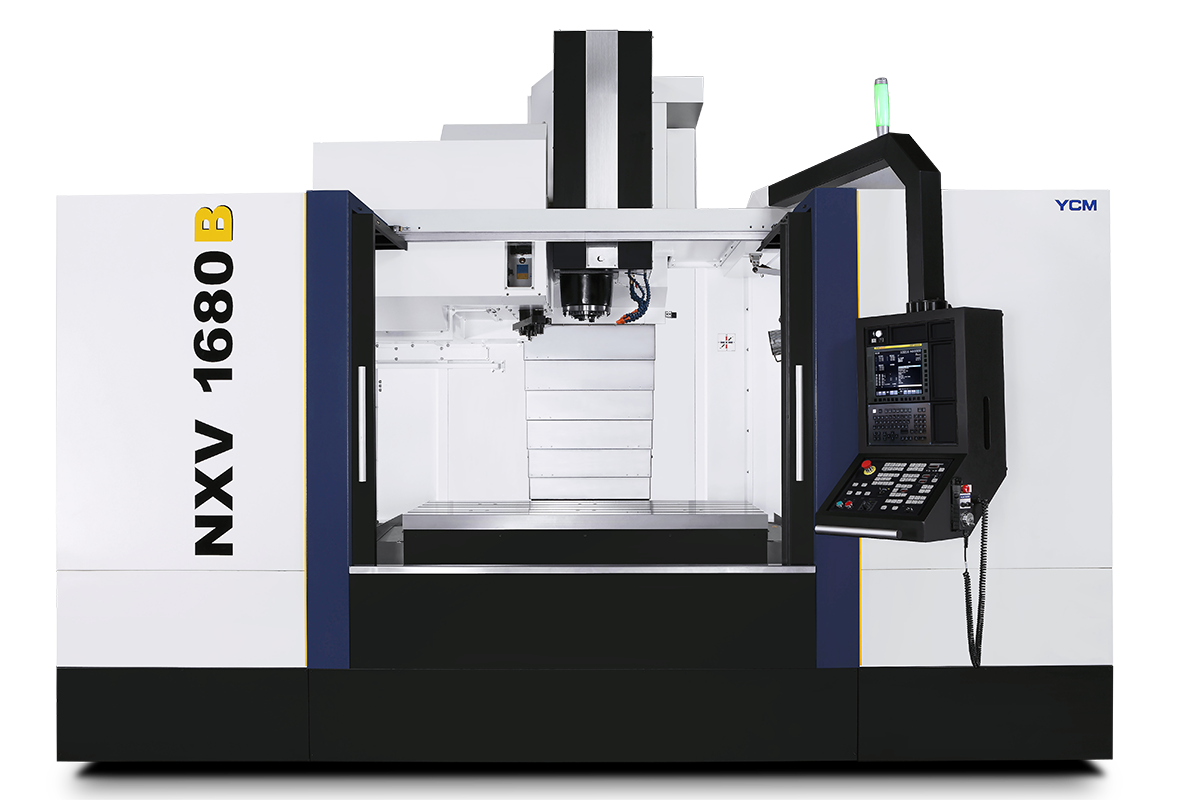

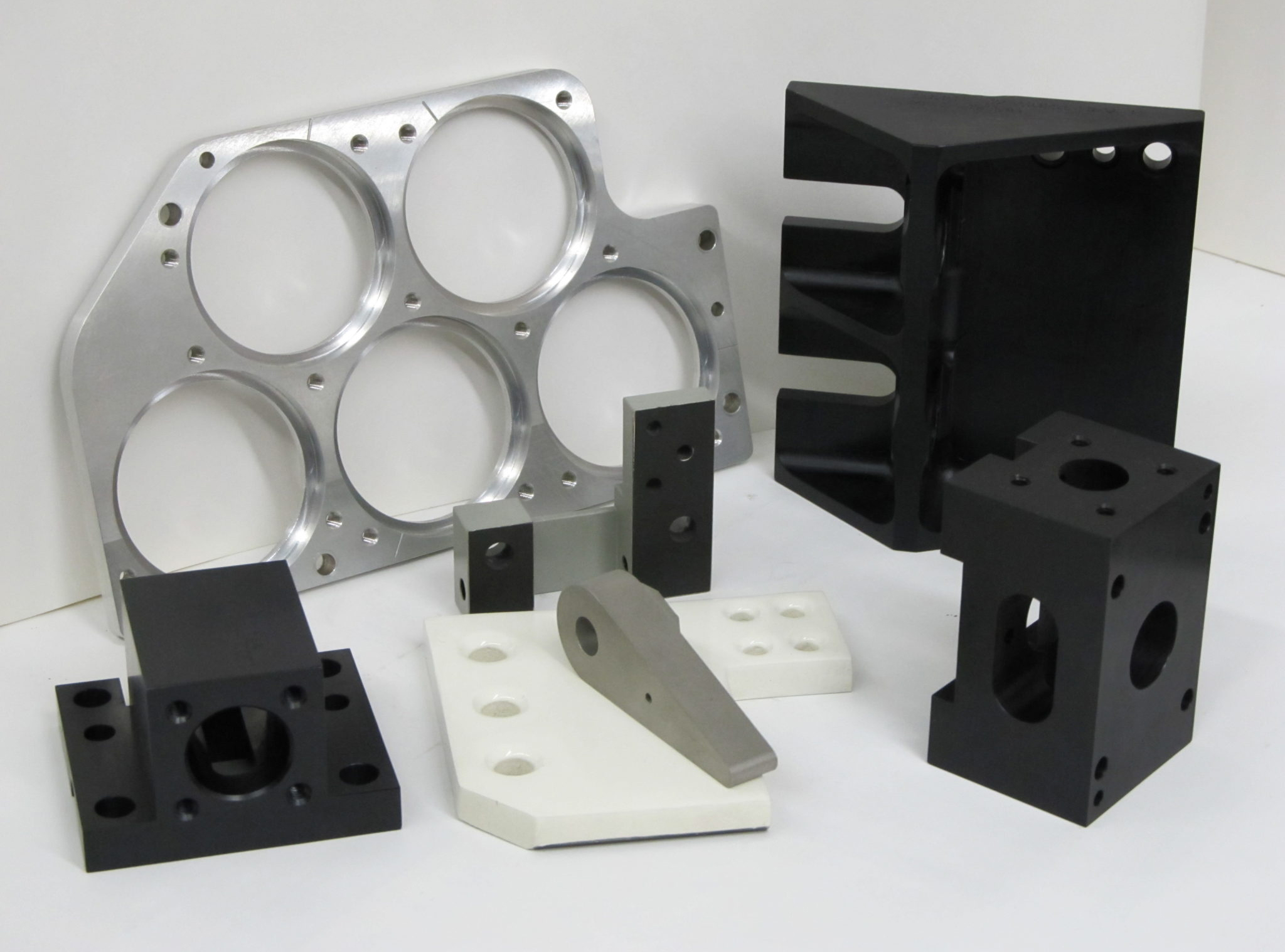

CNC MACHINING

CNC Machining Services NTM Inc. has been a certified supplier in the defense industry for over 40 years.

Our CNC Machining Services include:

- On-time delivery and quality performance

- CNC milling capabilities include up to 60 inches of travel

- CNC turning capabilities include state-of-the-art equipment with live tooling and sub-spindle work

We welcome all opportunities to quote machining and provide any assistance you may need for ongoing and upcoming projects.

Download our Capabilities Statement to learn more.

RETURN POLICY

NTM Inc. will accept any catalog item for return in new unused condition within 30 days of shipment for account credit. After 30 days, a 20% restocking fee will apply. No returns will be accepted on catalog items after 90 days. NTM Inc. will not accept returns on non-catalog or special tooling.

NTM Inc. guarantees braze on all Stubby® Boring Bars and will replace or re-head any returned Boring Bars inspected by NTM and deemed a manufacturer defect. Credits will not be issued.

NTM guarantees all special tooling will be made according to customer specs. Please notify us within 30 days of receipt if any issues arise and we will remake tools to align with customer-approved print. Credits will not be issued for special tooling.

** Modification of any NTM Inc. product or special voids guarantee.